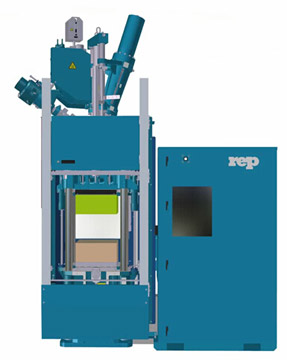

Injection Unit Y type

| Feed: Intake chamber with a helicoidal sleeve, and progressive start and stop of the extruder to prevent any risk of feed strip rupture. | In the case of compounds with widely varying viscosity, the extruder-uncoupling device ensures rapid cleaning of the screw and the check-valve area. |  | |

| Rigorous temperature control throughout all phases of the mixing process. Material temperature sensor at the extruder outlet for perfect self-heating control. | The traverse casting, “free”- mounted on the extruder-side absorbs thermal expansion and adjusting rings are used to ensure accurate centering of the injection unit. |  | |

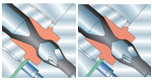

| The shape of the valve ensures an effective sweep and perfect renewal of the material with each cycle. The direct injection runner reduces head pressure drops. | Shot size metering accuracy is ensured by a check-valve with a short consistent stroke and a perfect seal. |  |

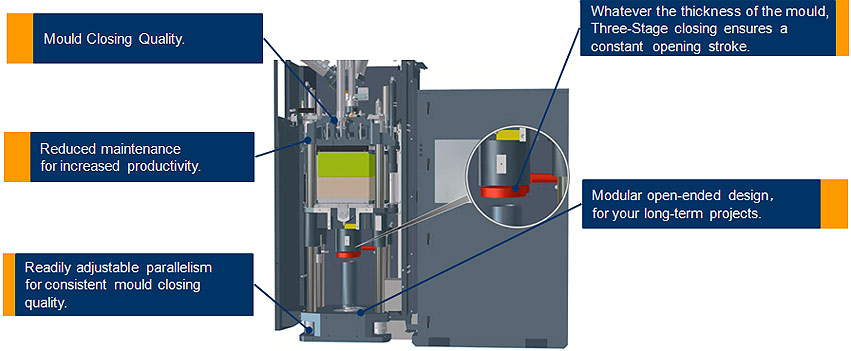

Almost Maintenance Free Closing Unit ----------------------------------------------------------------------------------------------------------

3-STEP CLOSING UNIT WITH CLAMPING BLOCK SYSTEM

● Strong for perfect mold clamping

● Floating columns

● Shoulderless columns, easy parallelism adjustment

● Modular and upgradable design

● Easy access for the operator

Options: Ejectors